What Is High Temp Gasket Material?

High temp gasket material refers to specialized sealing materials engineered to withstand elevated temperatures, often above 400°F (200°C), without losing strength or sealing ability. In engines, and other industrial equipment, there are different working areas needed different sealing demand.

Why High Temp Gasket Material Matters in Engine Sealing

Engine’s critical working areas, such as the cylinder head, exhaust, and fuel injector, expose gaskets to heat, pressure, and oil or fuel. Standard materials may fail under these conditions, so high temp gasket materials are necessary to ensure reliable sealing and longer service life.

8 High Temp Gasket Material for Engine Gasket

-

Composite Graphite

This type of high temp gasket material usually consists of 5 or 7 layers of perforated steel combined with graphite. Thanks to graphite’s excellent flexibility, it provides stronger adaptability and better sealing performance compared to traditional MLS gaskets.

This type of high temp gasket material usually consists of 5 or 7 layers of perforated steel combined with graphite. Thanks to graphite’s excellent flexibility, it provides stronger adaptability and better sealing performance compared to traditional MLS gaskets. -

Multi-layer Steel (MLS)

MLS is one of the most common high temp gasket materials, made from 2 to 7 layers of steel. Its layered structure ensures durability under high pressure and extreme temperature conditions.

MLS is one of the most common high temp gasket materials, made from 2 to 7 layers of steel. Its layered structure ensures durability under high pressure and extreme temperature conditions. -

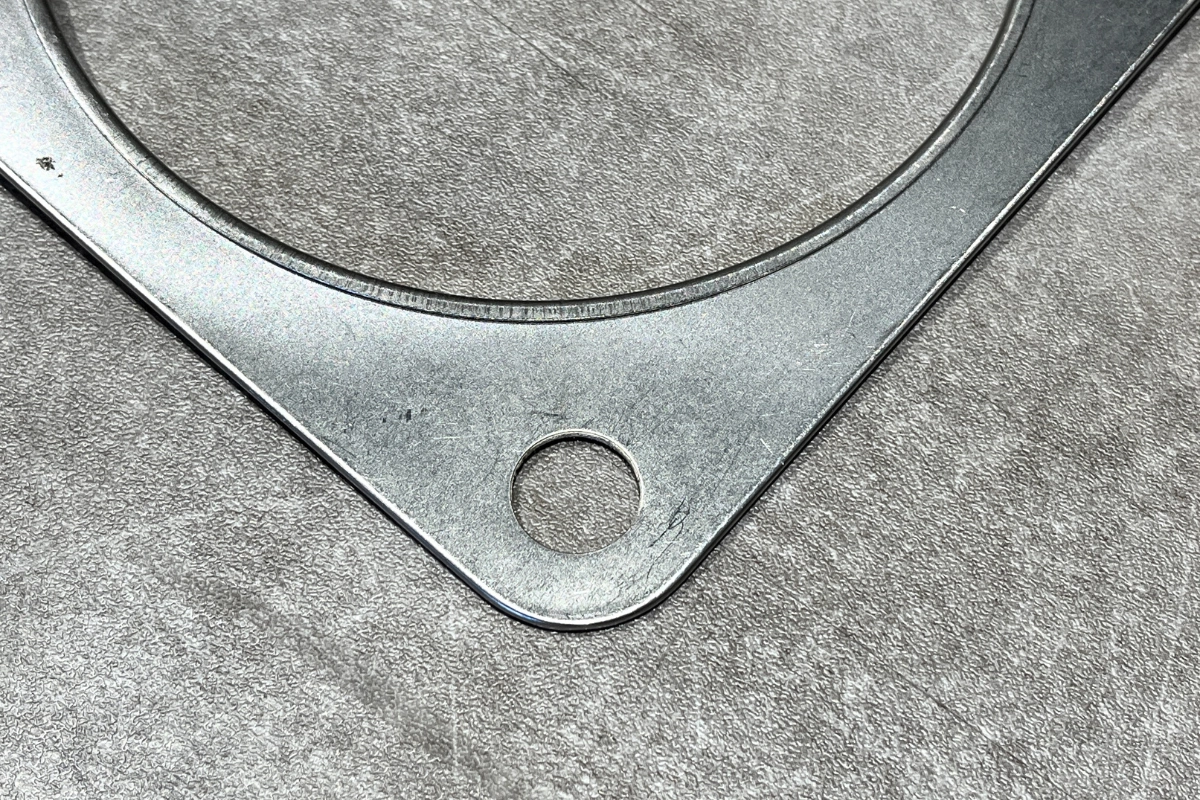

Single Layer Steel

A single steel layer is often coated with MoS2 (Molybdenum Disulfide) to enhance heat resistance. Sometimes the single layer gasket edges are embossed to improve sealing reliability.

A single steel layer is often coated with MoS2 (Molybdenum Disulfide) to enhance heat resistance. Sometimes the single layer gasket edges are embossed to improve sealing reliability. -

Steel with MoS2 Coating

MoS2 (Molybdenum Disulfide) is a compound with a silver-gray metallic luster, known for its excellent lubricating properties, high pressure resistance, and wear resistance. When applied to single-layer or multi-layer steel gaskets, it significantly boosts the thermal resistance and anti-friction properties of the high temp gasket material.

MoS2 (Molybdenum Disulfide) is a compound with a silver-gray metallic luster, known for its excellent lubricating properties, high pressure resistance, and wear resistance. When applied to single-layer or multi-layer steel gaskets, it significantly boosts the thermal resistance and anti-friction properties of the high temp gasket material. -

Sandwich Type

Sandwich type gasket combines double-jacketed steel with a filler such as graphite or non-asbestos. As mentioned above, graphite filler is often chosen for stronger sealing needs in high temperature environments.

Sandwich type gasket combines double-jacketed steel with a filler such as graphite or non-asbestos. As mentioned above, graphite filler is often chosen for stronger sealing needs in high temperature environments. -

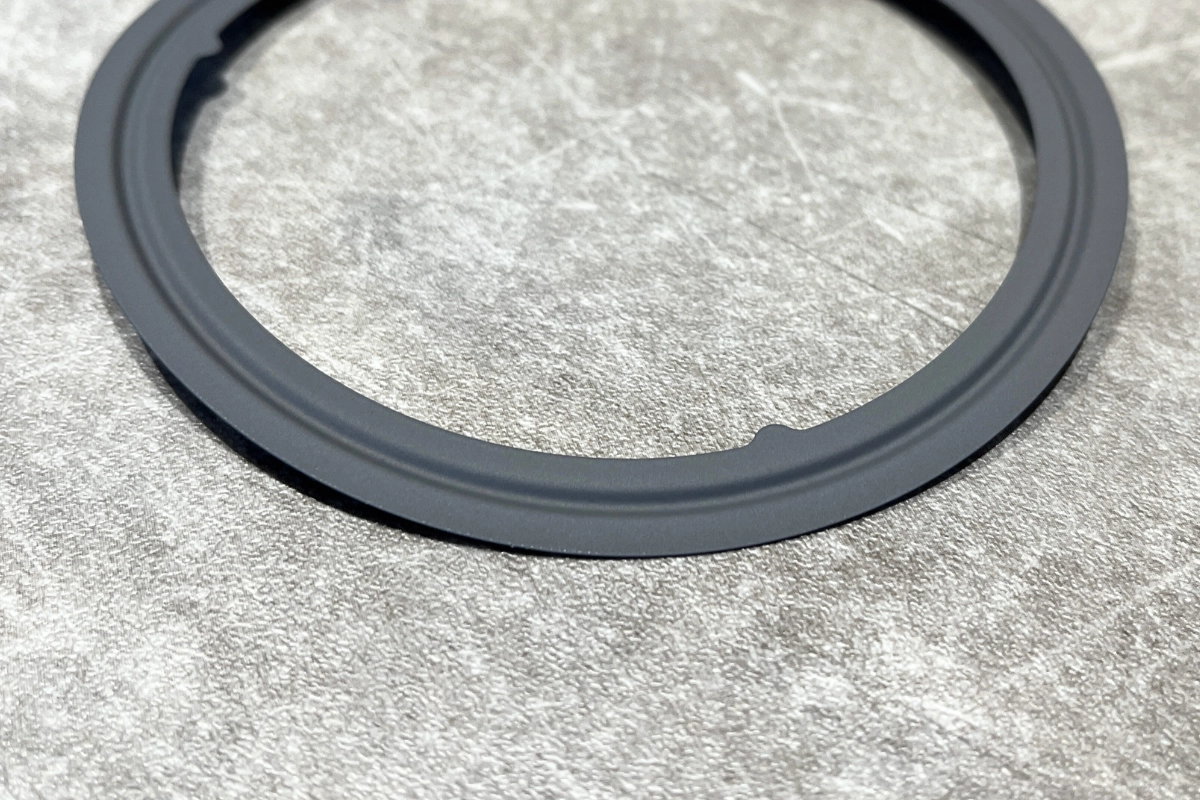

Metal Bonded with Rubber

A steel base bonded with rubber provides structural strength while maintaining flexibility. This combination allows the gasket to withstand high stress and ensures consistent sealing performance.

A steel base bonded with rubber provides structural strength while maintaining flexibility. This combination allows the gasket to withstand high stress and ensures consistent sealing performance. -

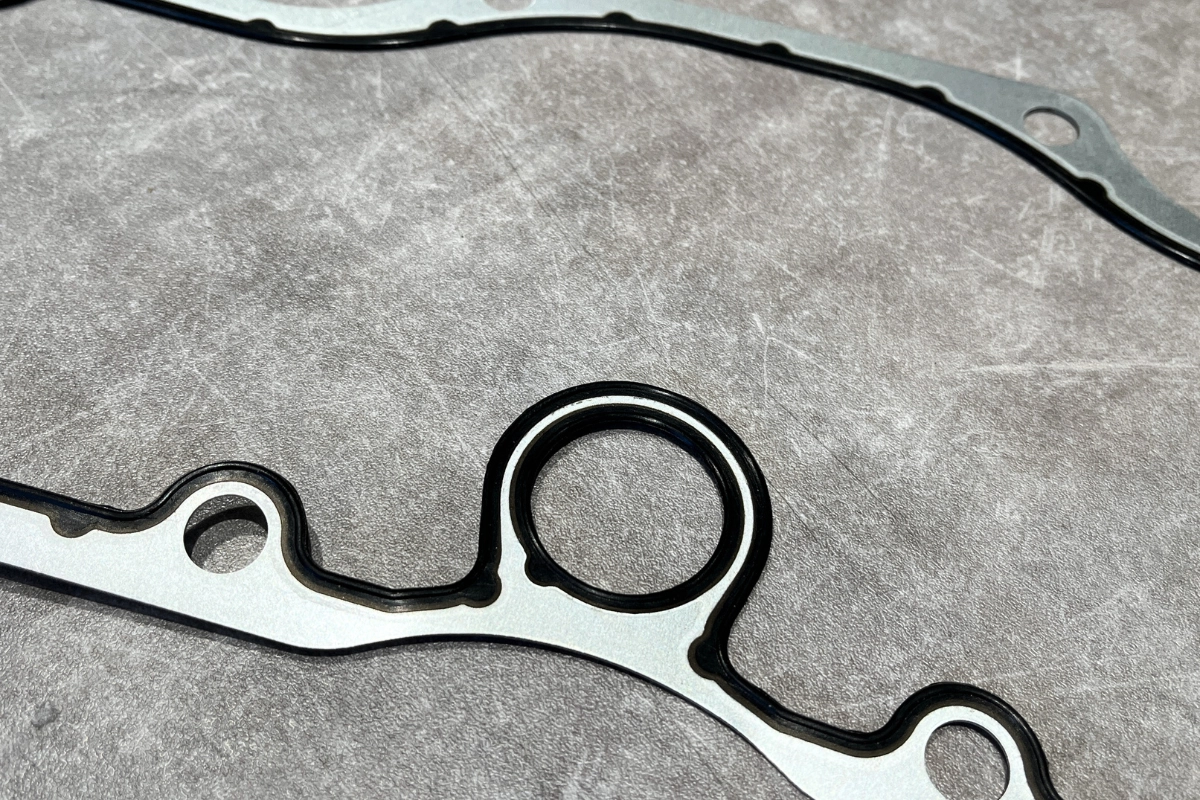

Rubber Coated Metal

This type of high temp gasket material features a thin rubber layer applied to the surface of the metal core. The rubber layer improves sealing adaptability, especially when FKM rubber is used, as it provides excellent elasticity to conform tightly to metal surfaces, at the same time, withstand high heat and maintain reliable sealing performance.

This type of high temp gasket material features a thin rubber layer applied to the surface of the metal core. The rubber layer improves sealing adaptability, especially when FKM rubber is used, as it provides excellent elasticity to conform tightly to metal surfaces, at the same time, withstand high heat and maintain reliable sealing performance. -

Rubber with PTFE Coating

Rubber coated with PTFE (Polytetrafluoroethylene) offers outstanding chemical and thermal resistance, mostly used for O-rings or small rectangular seals. This type of high temp gasket material is suitable for applications that demand both flexibility and resistance to aggressive fluids, such as fuel injector seals.

Rubber coated with PTFE (Polytetrafluoroethylene) offers outstanding chemical and thermal resistance, mostly used for O-rings or small rectangular seals. This type of high temp gasket material is suitable for applications that demand both flexibility and resistance to aggressive fluids, such as fuel injector seals.

High Temp Gasket Material for Head Gasket

The cylinder head gasket works in one of the most critical areas of the engine. No doubt, the gasket material for head gaskets must be highly resistant to heat and pressure. The common high temp gasket materials used here are composite graphite—especially for heavy-duty engines, graphite really does a great job; and also MLS and steel bonded with rubber.

To meet different needs, many head gasket constructions include multiple high temp gasket materials, such as MLS bonded with rubber or composite graphite combined with RCM assembly parts.

(You may also see some automotive engines using non-asbestos with silicone coating for head gaskets. It does work, but mostly for small engines. Large engines still require stronger materials.)

Read more about cylinder head gasket materials: Cylinder Head Gasket Material Types

High Temp Gasket Material for Exhaust Gasket

Exhaust gaskets operate under extremely high heat. The commonly used materials are similar to head gaskets: composite graphite, MLS, and MLS with MoS2 coating. For heavy-duty engines, I would say the most commonly used high temp gasket material for exhaust gaskets is steel with MoS2 coating, which shows just how suitable MoS2 is for high temperature applications.

Read more about exhaust gasket materials: 5 Types of Exhaust Gasket Material

High Temp Gasket Material for Injector Seal

For injector O-ring seals, the most common choice is rubber with PTFE coating, since PTFE is well known for its exceptional resistance to chemicals, high temperatures, and friction.

High Temp Gasket Material for Turbo Gasket

The most common gasket material for turbo gaskets is sandwich type. Many of our clients have asked us to customize the filler of sandwich type gaskets, replacing non-asbestos with graphite. Other high temp gasket materials for turbo gaskets include MLS and MLS with MoS2 coating.

Read more about turbo gasket materials: Turbocharger Gaskets Material

High Temp Gasket Material for EGR Gasket

For exhaust gas recirculation gaskets (EGR gaskets), the No.1 material is also steel with MoS2 coating. Some are made from single-layer steel, while others combine steel with graphite to achieve stronger sealing under heat.

Quick Q&A about High Temp Gasket Material

What gasket material is used for high temperature?

There are 8 high temp gasket materials: Composite Graphite, Multi-layer Steel (MLS), Single Layer Steel, MoS2-coated steel, Metal Bonded with Rubber, Rubber-coated metal, PTFE-coated rubber, and sandwich types.

Which high temp gasket material is best for heavy-duty diesel engines?

Composite graphite and MLS with MoS2 (Molybdenum Disulfide) coating are highly used for heavy-duty diesel engines due to their superior heat resistance and sealing performance under extreme conditions.

What are high temp gasket material for head gasket?

Composite graphite, MLS and Steel bonded with rubber are the most commonly used high temp gasket material for head gasket.

What are high temp gasket material for exhaust gasket?

Composite graphite, MLS and MLS with MoS2 coating are highly used high temp gasket material for exhaust gasket.

What are the advantages of rubber with PTFE coating?

PTFE-coated rubber gaskets provide excellent resistance to chemicals, high temperatures, and friction. They are widely used for injector O-rings or seals that require durability in aggressive environments.

|

Why can't I see product images? Product images, material details, and BOM are only available to MJ Members. To unlock this information, simply register here. |